Model NO.: DHC Separation Mode: Sedimentation Type Installation: Vertical Pressure: Low Pressure Trademark: Hongji Origin: China Type: Centrifuge Operating Type: Continuous Type Centrifuge Type:

Disc Centrifuge Condition: New Specification: 1570x 1440x 1900mm Hongji Disc Stack Centrifuge technolog can provide customer the best Made-in-China Centrifuge and separator . We are not only enrich only the separator and centrifuge technics but aslo have experiences for variety of different industry technics . Any questions or problem please contact us by further support. Centrifuge machine Standard design The machine consists of a frame that has a horizontal drive shaft with clutch and brake, worm gear , lubricating oil bath and vertical bowl spindle in the lower part. The bowl is mounted on top of the spindle in the lower part. The bowl is mounted on top of the spindle , inside the space formed by the upper parts of the frame , the ring solid cover, the collecting cover, and frame hood . The feed and liquid discharge system , including the paring disc pump for the heavy phase, also rests on this structure. All parts in contact with the process liquid are made of stainless steel. The bowl is of the solid-ejecting disc type with hydraulic operating system. The electric motor is of the variable frequency drive type or of controlled-torque type. Basic equipment Concentrator or purifier parts, inlet and outlet devices, revolution counter, set of erosion-protective parts ,illuminated sight glass box for light phase outlet , vibration switch , vibration-isolating base plate , flange motor, set of tool and standard set of spare. Optional extras Started equipment, frequency converter, discharge control panel, standard set of fittings, set of CIP valves and fittings and serviceability package for online viewing of separator status Material data Bowl body , hood and locking ring S.S304 Solids cover and frame hood S.S Frame bottom parts green cast iron , cald with In and outlet parts S.S Gasket and o-ring Nitrile rubber

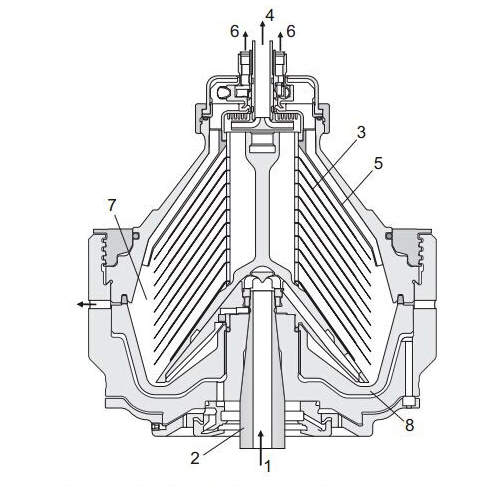

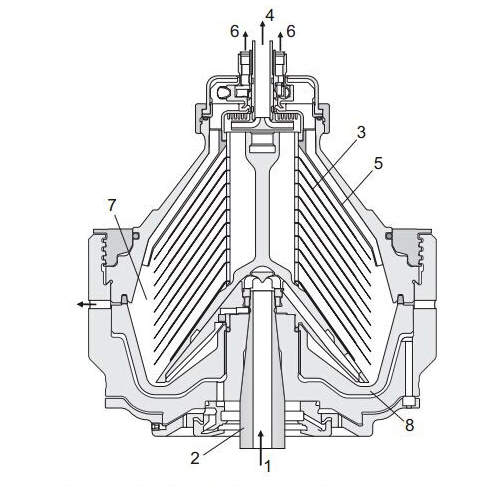

Operating principles Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1),and is accelerated in the distributor(2),which was specially designed to ensure smooth acceleration of the feed liquid(4). Leaving the distributor, the feed enters the disc stack(3). The separation into liquid-liquid-solid takes place between the discs, with the oil phase moving through the disc stack to the centre. When it reaches the centre, it is discharged through hole (5) and ejected into the collecting frame. The water and heavy solid separated from the oil move to the periphery, and the water flows via channels in the top disc(6) to the paring chamber, where it is pumped out of the rotor by means of a built-in paring disc(7).During purification, hot water is fed into the inlet of the bowl before the process liquid is introduced. The water forms a seal around the outer edge of the top disc. The solid collect in the periphery where they are discharged intermittently via the centrifuge cyclone. The solid are discharged by means of a hydraulic system, which forces the sliding bowl bottom(8)to drop down at preset suitable intervals, thus opening the solid ports at the bowl periphery

Centrifuge machine Main Parameter

Model | Bowl Speed(rpm) | Capacity(Per Hour) | Running Load(Watts) | Dimensions, Overall (mm) |

Width | Front-to-Back | Height |

250 | 8500 | 500-800 | 4.0 | 850 | 850 | 1200 |

270 | 7300 | 1000 | 4.0 | 950 | 950 | 1200 |

300 | 7150 | 1500 | 5.5 | 1025 | 1300 | 1300 |

360 | 7056 | 2000-3000 | 7.5 | 1500 | 1100 | 1500 |

400 | 7038 | 3000 | 7.5 | 1500 | 1100 | 1550 |

500 | 6600 | 5000-8000 | 15.5 | 1772 | 1500 | 1855 |

550 | 6200 | 8000-15000 | 18.5 | 1970 | 1560 | 1970 |

730 | 4900 | 50000-80000 | 55.0 | 2580 | 1980 | 2340 |

Our Services the suggestions from our customers, and offers the all-day, all-directional and top-grade market services.

The technical and after-sale services are listed as follows:

1. Provide free technical training, guidance and information of accessories.

2. Our technical staff could instruct our customers on the installation of connector and accessories on site, and deal with technical and quality issues.

3. We guarantee more than 10 years' service life of our products with 2 years' warranty and life maintenance.

4. 24-hour hot line: 86-13841990225. Once receive the customer complaints, we will response within 24 hours.

5. Free maintenance and replacement will be provided if defects result from quality failure of our product.

6. Our company will provide technical services by phone, fax, e-mail, etc., please refer to the contact details.

7. Our company will implement the contract strictly; deliver the products to location specified by our customers for free in accordance with the mode of transportation.

8. Our company will provide perfect after-sale services and technical support.

FAQ

1.Is your price competitive? My price is not the lowest in China as for high quality,but we promise for the same quality and collocation,my price is the most favorite,for the same price ,my quality is definitely superior.to other brand. 2.Do you have OEM service?Do you supply the parts? Yes,we do,as long as you provide us your drawing and detailed requirements. 3.Do you have agent or service center in my country? We have some partnership in several countries as Indonesia,Brazil,USA etc,you are warmly welcomed to work as our agent,at this moment,we have no service centers abroad,but we can provide overseas spot and online technical service in time. 4.How can we easily find out the most fit centrifuges? We have experienced engineer team to help you make the model selection,as long as you provide us the detailed processing material characteristics. 5.What payment mode you accept? TT , LC at sight or others . Note: The prodcution capacity is based on water only, just for reference. Different feeding solution will of different production capacity. If you have special requirements, please feel free to contact us. Contact Information: Contact name: Jessie Zhao Phone: +86-18641998048

Whats App: +8618641998048

Skype: +8618641998048

Wechat: 18641998048

Contact us if you need more details on Disc Stack Centrifuge. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Disc Centrifuge、Centrifuge for Biotech. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Disc Centrifuge

Operating principles Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1),and is accelerated in the distributor(2),which was specially designed to ensure smooth acceleration of the feed liquid(4). Leaving the distributor, the feed enters the disc stack(3). The separation into liquid-liquid-solid takes place between the discs, with the oil phase moving through the disc stack to the centre. When it reaches the centre, it is discharged through hole (5) and ejected into the collecting frame. The water and heavy solid separated from the oil move to the periphery, and the water flows via channels in the top disc(6) to the paring chamber, where it is pumped out of the rotor by means of a built-in paring disc(7).During purification, hot water is fed into the inlet of the bowl before the process liquid is introduced. The water forms a seal around the outer edge of the top disc. The solid collect in the periphery where they are discharged intermittently via the centrifuge cyclone. The solid are discharged by means of a hydraulic system, which forces the sliding bowl bottom(8)to drop down at preset suitable intervals, thus opening the solid ports at the bowl periphery

Operating principles Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe (1),and is accelerated in the distributor(2),which was specially designed to ensure smooth acceleration of the feed liquid(4). Leaving the distributor, the feed enters the disc stack(3). The separation into liquid-liquid-solid takes place between the discs, with the oil phase moving through the disc stack to the centre. When it reaches the centre, it is discharged through hole (5) and ejected into the collecting frame. The water and heavy solid separated from the oil move to the periphery, and the water flows via channels in the top disc(6) to the paring chamber, where it is pumped out of the rotor by means of a built-in paring disc(7).During purification, hot water is fed into the inlet of the bowl before the process liquid is introduced. The water forms a seal around the outer edge of the top disc. The solid collect in the periphery where they are discharged intermittently via the centrifuge cyclone. The solid are discharged by means of a hydraulic system, which forces the sliding bowl bottom(8)to drop down at preset suitable intervals, thus opening the solid ports at the bowl periphery Centrifuge machine Main Parameter

Centrifuge machine Main Parameter